0.1~2.2kW 1phase 200V

0.1~3.7kW 3phase 200V

0.4~7.5kW 3phase 400V

C100

LSLV

Compact Drive

Compact

Convenient

Compact

04

Convenient

06

Model & Type / Basic Specifications

08

Control

10

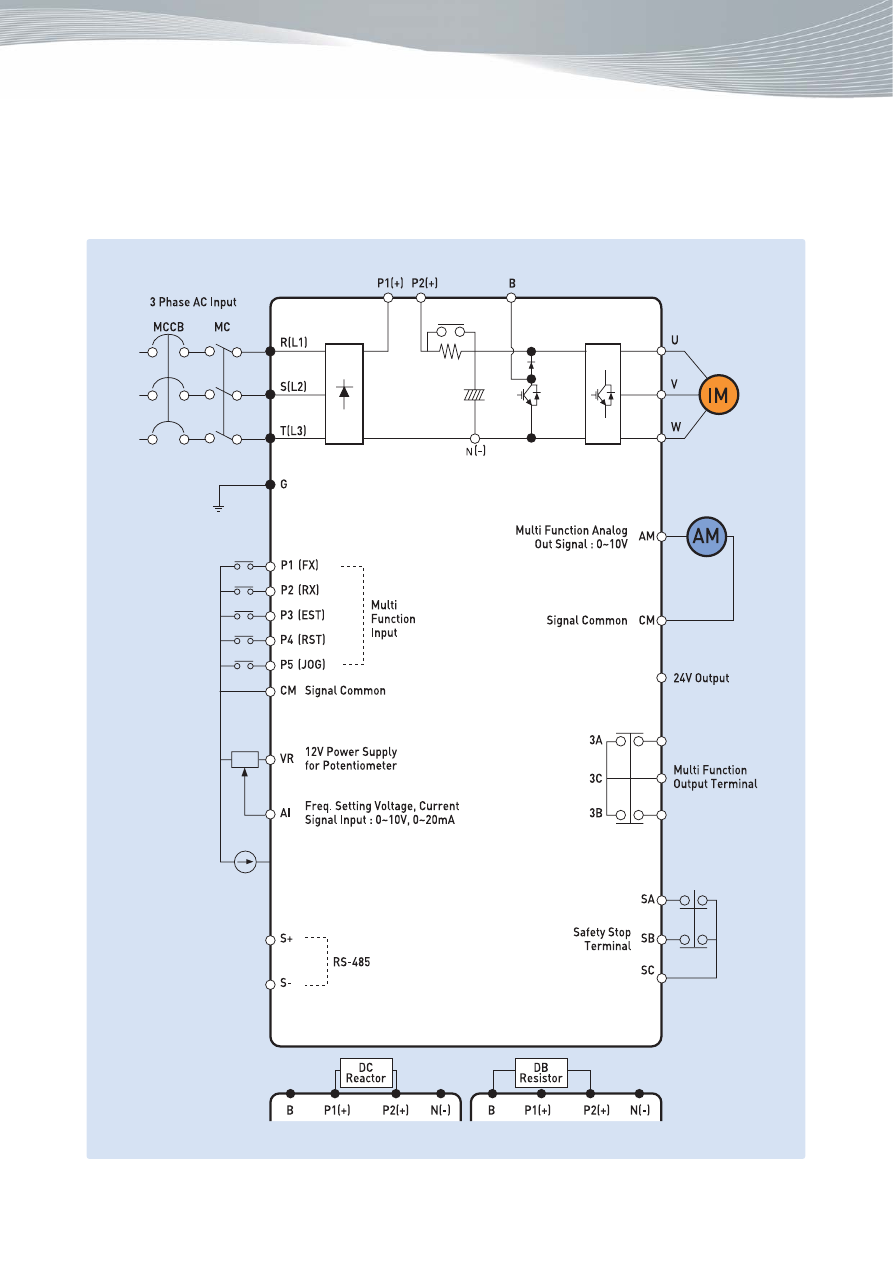

Connection Diagram

11

Terminal Function

12

Control Circuit Terminal

13

Keypad Usage & Function

14

Moving to Other Parameter Groups & Codes

15

Braking Resistors and Peripheral Devices

17

Dimensions

18

C O N T E N T S

LSLV-C100, the cost effective and easy-to-install,

compact drive will enhance your machine performance

LSLV-C100 Provides Optimized Solution

to Global Customers

02_03

Compact Drive LSLV-C100

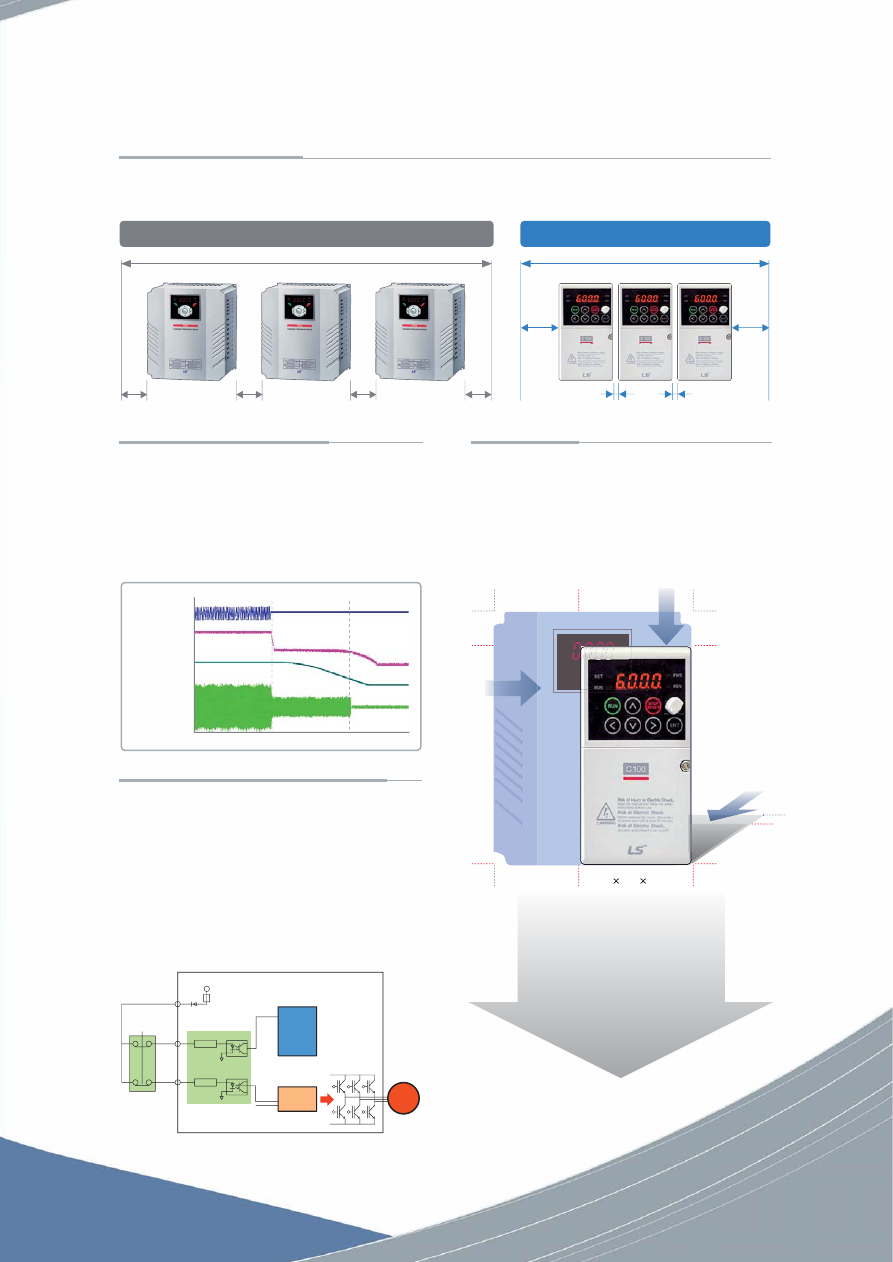

COMPACT

Size Reduction

Standard 200V 1.5kW

Features

No Need for 'Big Drives'.

Compact but Optimized LSLV-C100

Will do the Job

H

D

W

The control can be significantly reduced thanks to C100's 'side-by-side' installation.

Side-by-Side Installation

Volume size is reduced by up to 33% compared to

existing products (iG5A) by arranging main components

optimally using thermal analysis and 3D design

(Standard 0015C100-1/0022C100-2/0022C100-4)

Size Reduction

Size Reduction

Standard 200V 1.5kW

04_05

Compact Drive LSLV-C100

By using the regenerated power from the decelerating

load, KEB function automatically protects machine by

providing safe(controlled) braking in case of power

outage.

KEB for Safe Operating Stop

in the Event of Power Failure

100

128

145mm

50mm

50mm

50mm

50mm

iG5A(500mm)

C100(364mm)

30mm

30mm

2mm

2mm

•

If a machine needs safe standstill functionality in

case of emergency, the connection of SA, SB, and SC

terminals that is shorted normally will be opened to

block the drive output.

•

Easy to comply with safety requirements at system

level by adding safe input functions complying with

EN ISO 13849-1 PLd and EN 61508 SIL2

(EN60204-1, stop category 0)

Note)

Safety relay not included

Compliance with Safety Requirements

24V

SC

SA

SB

Safety Stop

Relay

/SAT

A

CPU

PWM

Fault

PWM

IM

Gate

Block

/SAT

B

/OC2

33

%

Input Voltage

DC-ink Voltage

Operating

Frequency

Output Current

CONVENIENT

Simple Operation and Easy Maintenance

Features Enhance Customers’ Convenience.

Features

•Provides external potentiometer for easier

frequency control

•Addtional 0~5V analog input for freqeuncy

control

Integrated Potentiometer

User Convenience by

Simple Operation

Drive view software allows drive/System monitoring on a PC and easy maintenance of drive/Motor parameters

Note)

Drive View sw available by 2014. Nov

•Window based graphic user interface (GUI)

•LS-BUS, Modbus-RTU

•Connecting up to 31 drives

•Great reporting function

•Event logging

•Integrated control console

•Offline editing function

•Data upload/download

•4-channel oscilloscope

•Trigger function

DriveView

PC-based Easy Maintenance of Drive/Motor Parameters

Designed to Select Between

Heavy and Light Load

Dual Rating

User can easily replace a fan without opening

the drive cover

Easy Fan Maintenance

06_07

Compact Drive LSLV-C100

Converter

•Heavy load operation: 150% of rated current, 60 sec.

•Light load operation: 100% of rated current, 60 sec.

Overload

Withstand

Power

1Phase 200V

3Phase 200V

3Phase 400V

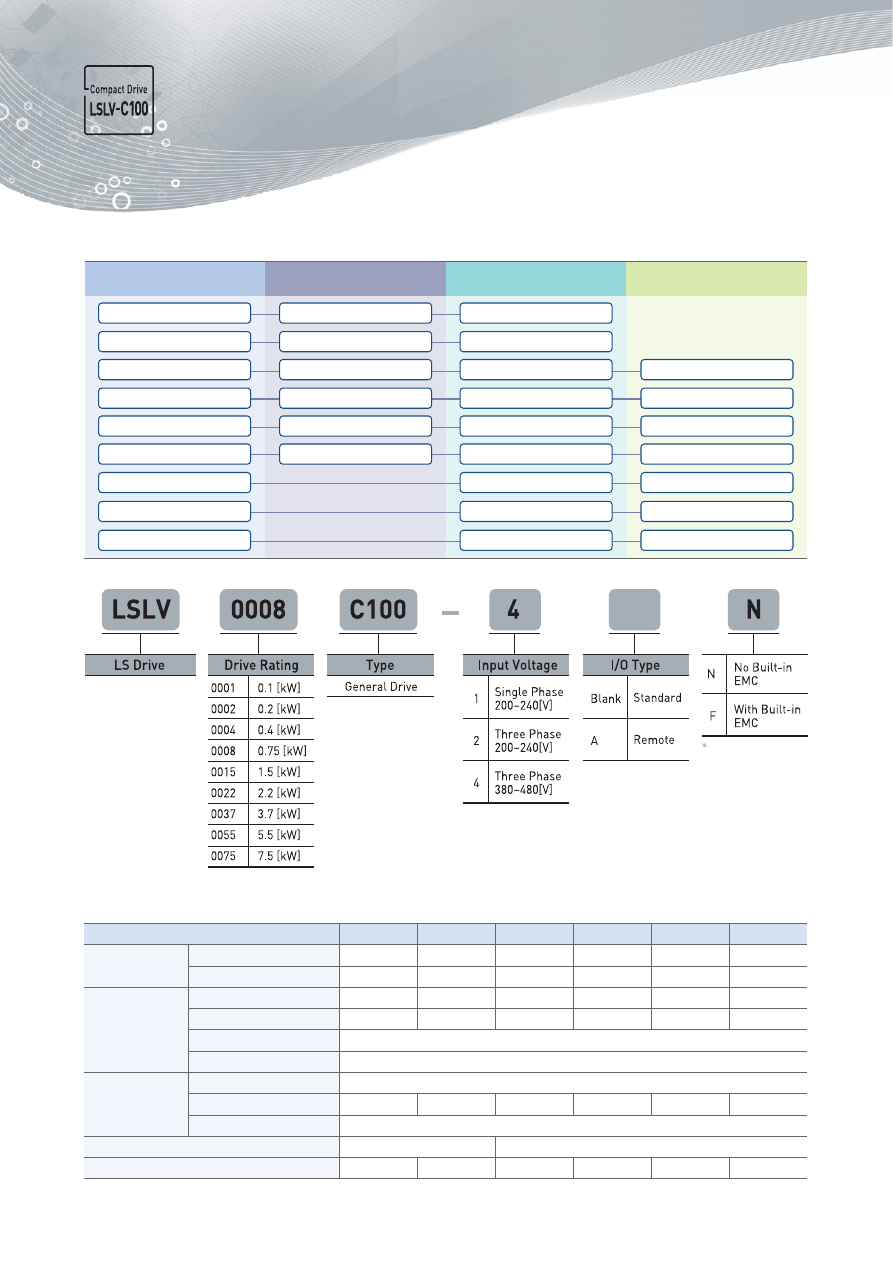

LSLV

□□□□C100-1□

0001

0002

0004

0008

0015

0022

Applicable Motor

1)

Output Ratings

Input Ratings

Cooling Type

Weight of Drive [kg]

[HP]

[kW]

Rated Capacity [kVA]

2)

Rated Current[A]

3)

Max. Output Frequency

Max. Output Voltage [V]

Rated Voltage [V]

Rated Current [A]

Rated Frequency

1/8

0.1

0.3

0.8

400 [Hz]

4)

Three Phase 200 ~ 240V

5)

Single Phase 200 ~ 240 VAC (-15% ~ +10%)

50 ~ 60 [Hz] (

±5%)

Natural Cooling Forced Cooling

1/4

0.2

0.5

1.4

1/2

0.4

1.0

2.5

1

0.75

1.9

5.0

2

1.5

3.0

8.0

3

2.2

4.2

11

0.55

0.55

0.8

1.22

1.42

1.97

Input and Output Specifications : Single-phase Input Voltage (200V)

Drives of capacity 0.1~7.5kW with

EMC filter are under development

0.1~2.2kW-1 : release by May. 2015

0.4~7.5kW-4 : release by May. 2015

0.1 kW

0.2 kW

0.4 kW

0.8 kW

1.5 kW

2.2 kW

3.7 kW

5.5 kW

7.5 kW

LSLV0001C100-1

LSLV0002C100-1

LSLV0004C100-1

LSLV0008C100-1

LSLV0015C100-1

LSLV0022C100-1

LSLV0004C100-4

LSLV0008C100-4

LSLV0015C100-4

LSLV0022C100-4

LSLV0037C100-4

LSLV0055C100-4

LSLV0075C100-4

Model & Type / Basic Specifications

LSLV0001C100-2

LSLV0002C100-2

LSLV0004C100-2

LSLV0008C100-2

LSLV0015C100-2

LSLV0022C100-2

LSLV0037C100-2

LSLV0055C100-2

LSLV0075C100-2

1.4

2.8

5.5

11

14.1

24

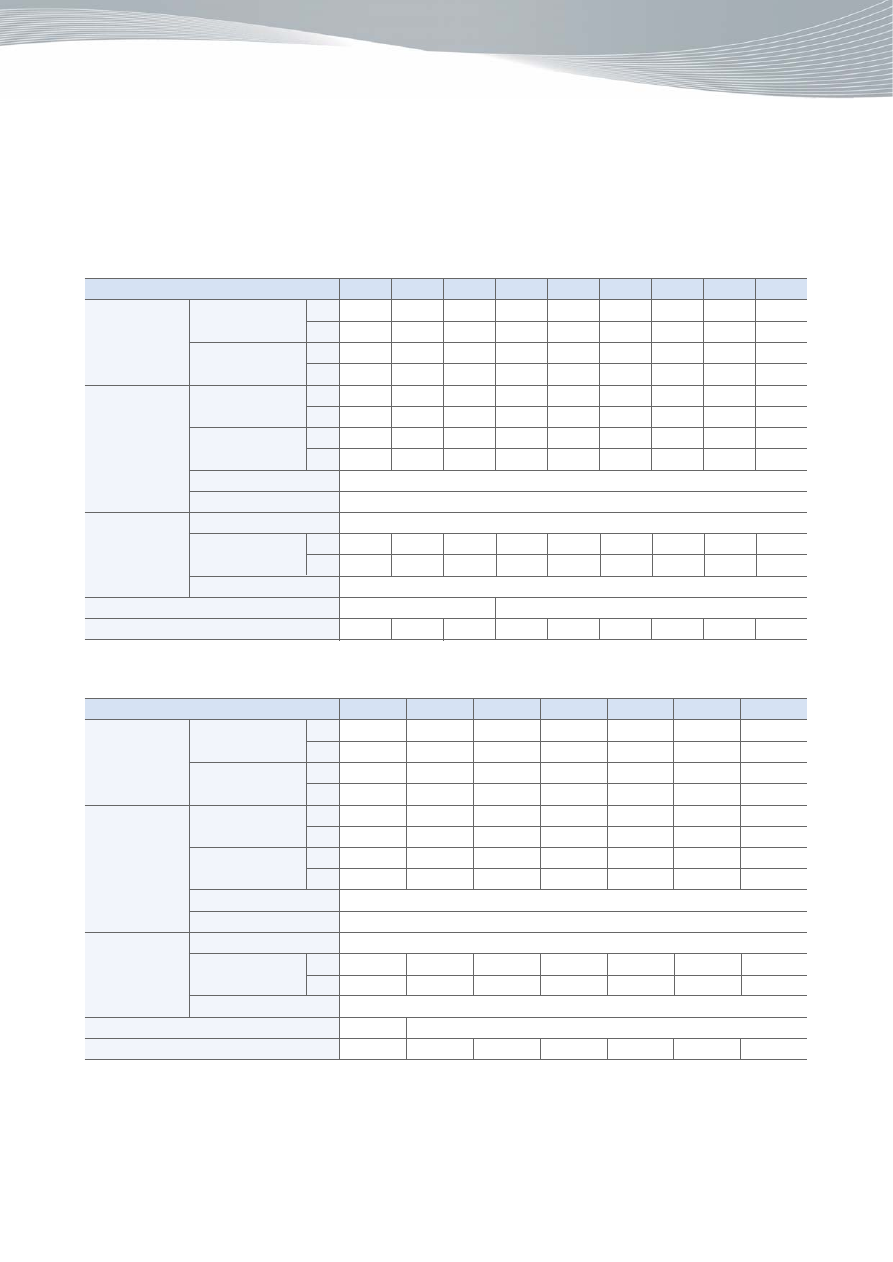

LSLV

□□□□C100-2□

0001

0002

0004

0008

0015

0022

0037

Applicable Motor

1)

Output Ratings

Input Ratings

Cooling Type

Weight of Drive [kg]

Max. Output Frequency

Max. Output Voltage [V]

Rated Voltage [V]

Rated Frequency

[HP]

[kW]

[HP]

[kW]

HD

ND

HD

ND

HD

ND

Rated Capacity

[kVA]

2)

Rated Current [A]

3)

Rated Current [A]

3)

1/8

0.1

1/4

0.2

0.3

0.4

0.7

1.1

HD

ND

400 [Hz]

4)

Three Phase 200 ~ 240V

5)

Three Phase 200 ~ 240 VAC (-15% ~ +10% )

50 ~ 60 [Hz] (

±5%)

Natural Cooling

Forced Cooling

1/4

0.2

1/2

0.4

0.5

0.7

1.5

1.8

1/2

0.4

1

0.75

1.0

1.3

2.0

3.1

1

0.75

1.5

1.1

1.9

2.4

5.8

6.3

2

1.5

3

2.2

3.0

3.8

7.5

10.0

3

2.2

4

3.0

4.2

5.2

11.0

12.0

5

3.7

5.4

4.0

6.1

7.6

18.9

18.0

0.55

0.55

0.8

0.8

1.22

1.97

0055

7.5

5.5

10

7.5

9.1

12.1

22.1

30.0

3.3

0075

10

7.5

15

11.0

12.2

16.3

28.6

40.0

3.3

1.42

Input and Output Specifications : Three-phase Input Voltage (200V)

LSLV

□□□□C100-4□

0004

0008

0015

0022

0037

0055

0075

Applicable

Motor

1)

Output Ratings

Input Ratings

Cooling Type

Weight of Drive [kg]

Max. Output Frequency

Max. Output Voltage [V]

Rated Voltage [V]

Rated Frequency

[HP]

[kW]

[HP]

[kW]

HD

ND

HD

ND

HD

ND

Rated Capacity

[kVA]

2)

Rated Current [A]

3)

Rated Current [A]

3)

1/2

0.4

1

0.75

1.0

1.2

1.25

2.0

HD

ND

400 [Hz]

4)

Three Phase 380 ~ 480V

5)

Three Phase 380 ~ 480 VAC (-15% ~ +10%)

50 ~ 60 [Hz] (

±5%)

Natural Cooling

Forced Cooling

Note

1) Indicates the maximum applicable motor capacity when using a 4-pole standard motor of HIGEN.

Note

2) Rated capacity is based on 220V for 200V class and 440V for 400V class.

Note

3) When Carrier frequency setting (H39) is above 6kHz.

Note

4) The max. frequency setting range can be 120Hz when H40 is set to 3 (Sensorless vector control)

Note

5) The maximum output voltage cannot be higher than the input voltage and it can be programmable below input voltage.

1.0

0.75

1.5

1.1

1.9

2.4

2.5

3.1

2.0

1.5

3

2.2

3.0

3.8

4.0

5.1

3.0

2.2

4

3.0

4.2

5.2

5.5

6.9

5.0

3.7

5.4

4.0

6.1

7.6

8.0

10.0

0.8

7.5

5.5

10

7.5

9.1

12.1

12.0

16.0

3.3

10.0

7.5

15

11.0

12.2

16.3

16.0

23.0

3.4

0.8

1.22

1.42

1.97

Input and Output Specifications : Three-phase Input Voltage (400V) Class

08_09

Compact Drive LSLV-C100

0.7

1.1

1.5

1.9

2.0

3.9

5.8

7.3

7.5

10.8

11.0

13.9

18.9

24

22.1

28.6

28.6

41.2

1.8

2.1

3.2

4.3

4.4

5.9

6

8.1

10.4

14

11.0

14.7

14.4

21.9

Controller

Control Type

Frequency Precision Setting

Frequency Precision

Dynamic Torque 20%

Braking

V/F Pattern

Overload Capacity

Torque Compensation

Max. Brake Torque

Time/%ED

V/F control, sensorless vector control

Linear, squared, user V/F

HD : 150%/ 1min; ND: 110%/ 1min

Manual/Auto torque compensation

20%

1)

150%

2)

when using optional DB resistor

Digital command: 0.01Hz

Analog command: 0.06Hz (Max. frequency: 60Hz)

Operation by digital command: 0.01% of max. output frequency.

Analog command operation: 0.1% of max. output frequency.

Control

Note

1) Average braking torque during Decel to stop a motor.

Note

2) Refer to manual page 13-6 for DB resistor specification.

Protection Degree

Application Temperature

Storage Temperature

Application Humidity

Altitude/Vibration

Atmospheric Pressure

Installation Environment

Opening (IP 20)

-20°C ~ 65°C

Below relative humidity 90% RH (no condensation)

Below 1000m, 5.9/sec

2

(0.6G)

70~106 kPa

There shall not be corrosive air, combustible gas, oil mist, dust and so on.

HD operation: - 10 ~ 50°C (no freezing)

ND operation: - 10 ~ 40°C (no freezing)

(But as for operation at 50°C, if the drive adopts VT (HD) load,

it is recommended to use the load blow 80%).

Structure and Application Environment

Faults

Alarm

Momentary Power Loss

1)

Stall prevention, overload

Over voltage, low voltage, over current, short circuit, ground current detection, drive overheat,

motor overheat, input and output phase loss, overload protection, communication error,

loss of frequency command, hardware fault, cool fan trip, brake error.

Protective Function

Note

1) the rated input voltage is 220V for 200V class, 440V for 400V class, and the rated input is subject to HD.

Operation Mode

Frequency Setting

Operational Functions

Input

Output

P1 ~ P5

Multi-function Terminals

(5 pcs) P1 ~ P5

Multi-function Relay

Analog Output

Keypad / Terminal / Communication operation

Functions: Forward/Reverse operation, emergency stop, fault reset, Jog operation,

multi-step frequency – high, mid and low, multi-step Accel/ Decel- High, Mid, Low,

DC braking at stop, 2

nd

motor select, Up/Down operation function

(Increase/Decrease of frequency), 3-wire operation, External fault signal input

(contact A/B), General operation switched during PID operation, 2

nd

Source,

Analog hold, Accel/Decel stop, Up/Down Save Freq, jog forwards/reverse operation.

Analog type: 0 ~ 10[V], 0 ~ 20[mA]

Digital type: Keypad

Panel potentiometer

Below 16 msec: Continuous operation

Above 16 msec: Auto restarting.

0 ~ 10Vdc (less than 10mA): Choose among Output Freq, Output Current, Output Voltage,

DC link selectable.

Fault output and drive status output

Less than (N.O., N.C.) AC250V 1A,

Less than DC 30V 1A

PID control, Up-Down operation, 3-wiring operation

Optional NPN / PNP

Operation

10_11

Compact Drive LSLV-C100

Connection Diagram

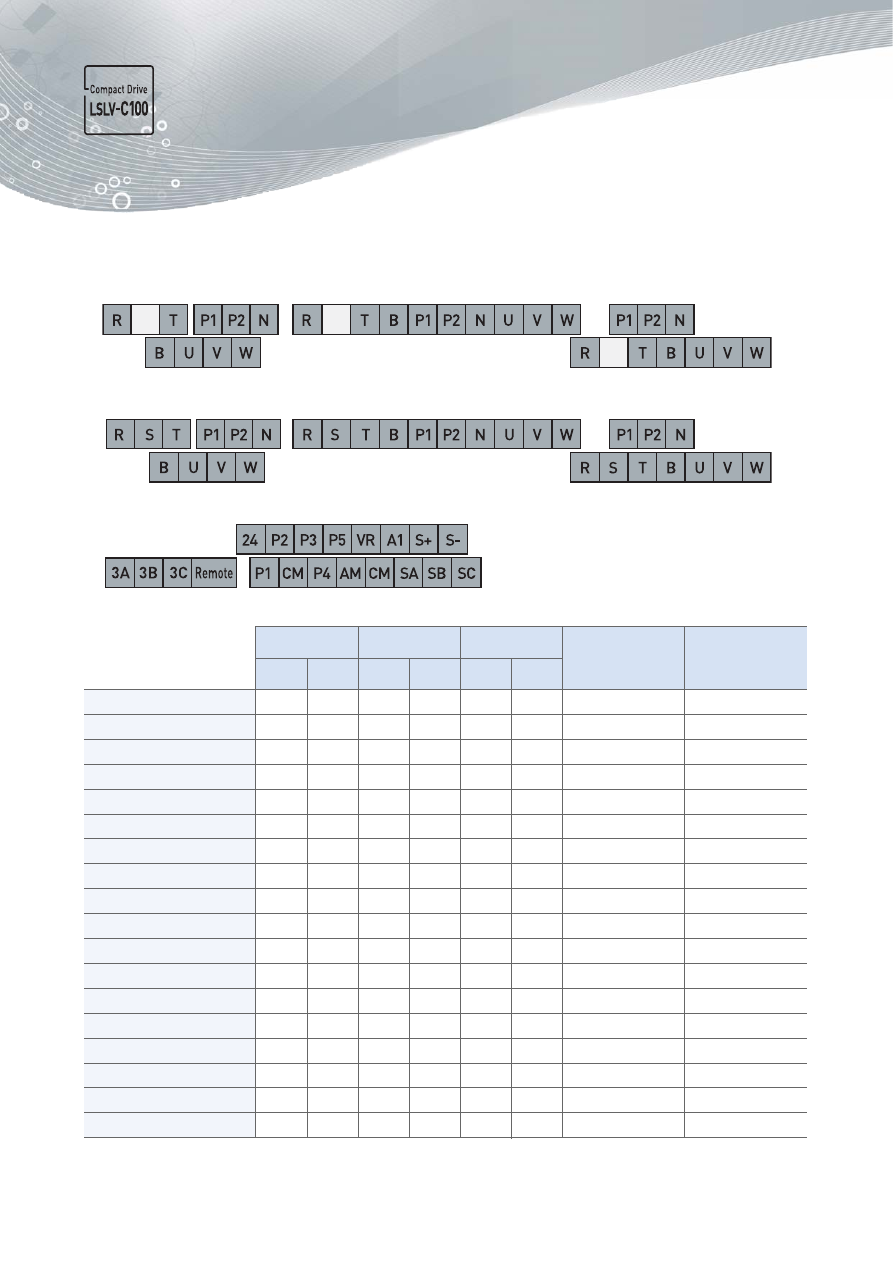

Terminal Function

R.S.T Size

AWG

mm

2

U,V,W Size

AWG

mm

2

Ground Size

Terminal Screw

Size

Screw Torque

(kgf.cm)/Ib-in

AWG

mm

2

LSLV0001C100-1

LSLV0002C100-1

LSLV0004C100-1

LSLV0008C100-1

LSLV0015C100-1

LSLV0022C100-1

LSLV0015C100-2

LSLV0022C100-2

LSLV0037C100-2

LSLV0055C100-2

LSLV0075C100-2

LSLV0004C100-4

LSLV0008C100-4

LSLV0015C100-4

LSLV0022C100-4

LSLV0037C100-4

LSLV0055C100-4

LSLV0075C100-4

0.1kW~0.4kW(Single Phase 200V)

0.75kW~1.5kW(Single Phase 200V)

2.2kW(Single Phase 200V)

0.1kW~0.75kW(Three Phase 200V / 400V)

5.5kW~7.5kW(Three Phase 200V / 400V)

1.5kW~2.2kW(Three Phase 200V / 400V)

3.7kW(Three Phase 200V / 400V)

2

2

2

2

2

3.5

2

2

3.5

6

6

2

2

2

2

3.5

3.5

3.5

14

14

14

14

14

12

14

14

12

10

10

14

14

14

14

12

12

12

2

2

2

2

2

3.5

2

2

3.5

6

6

2

2

2

2

3.5

3.5

3.5

14

14

14

14

14

12

14

14

12

10

10

14

14

14

14

12

12

12

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

5.5

5.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

12

12

12

12

12

12

12

12

12

10

10

12

12

12

12

12

12

12

M3.5

M3.5

M3.5

M3.5

M3.5

M4

M3.5

M3.5

M4

M4

M4

M3.5

M3.5

M3.5

M3.5

M4

M4

M4

10/8.7

10/8.7

10/8.7

10/8.7

10/8.7

15/13

10/8.7

10/8.7

15/13

15/13

15/13

10/8.7

10/8.7

10/8.7

10/8.7

15/13

15/13

15/13

12_13

Compact Drive LSLV-C100

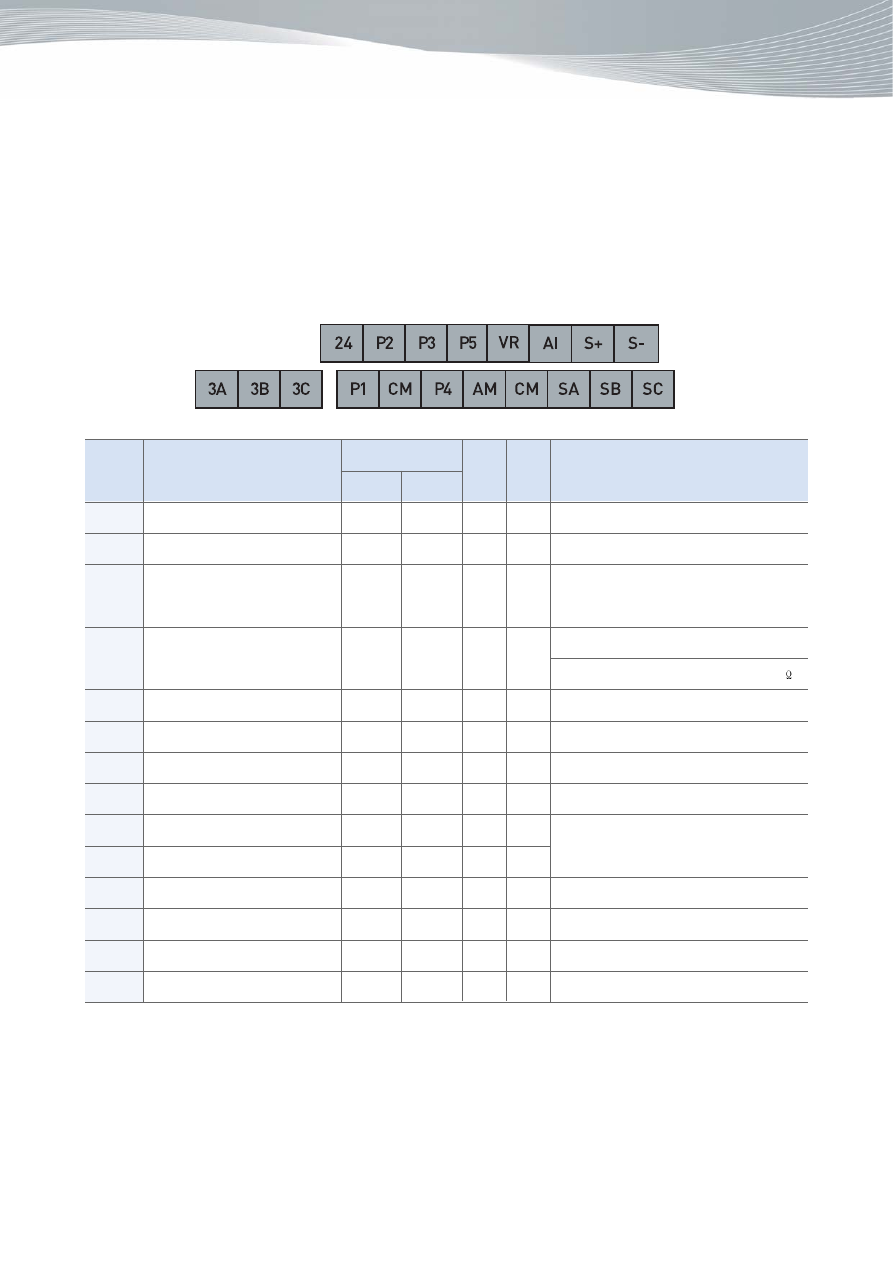

Control Circuit Terminal

Wire Size(mm

2

)

Stranded

Single Wire

Specification

Terminal Description

T/M

Torque

[Nm]

Screw

Size

P1~P5

CM

AM

S+

S-

24

3A

3B

3C

SA

SB

SC

VR

Multi-function input terminal P1-P5

Common terminal

Multi-function analog output terminal

RS485 communication terminal

RS485 communication terminal

External 24V power supply

Multi-function relay output A

Multi-function relay output B

Multi-function relay common terminal

Safe stop connection terminal A

Safe stop connection terminal B

Safety power supply (24V)

Power supply for analog

Output voltage: 12V, Max output current: 10mA

Potentiometer:1 ~ 5kohm

AC 250V, less than 1A

DC 30V, less than 1A

Max output voltage: 11[V], Max output current: 10mA

Max output current: 100mA

AI

Analog (voltage and current)

input terminal

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

M2.6

M2.6

M2.6

M2.6

M2.6

M2.6

M2.6

M2.6

M2.6

M2.6

M2.6

M2.6

M2.6

M2.6

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

0.4

Input voltage:0~10V

Input current:0 ~ 20mA, Internal resistance: 250

Control Terminal Specification

Note

1) Tie the control wires mote than 15cm away from the control terminals. Otherwise, it interferes front cover reinstallation.

Note

2) Use Copper wires rated 600V, 75 °C and higher.

Note

3) Use the recommended tightening torque when securing terminal screws.

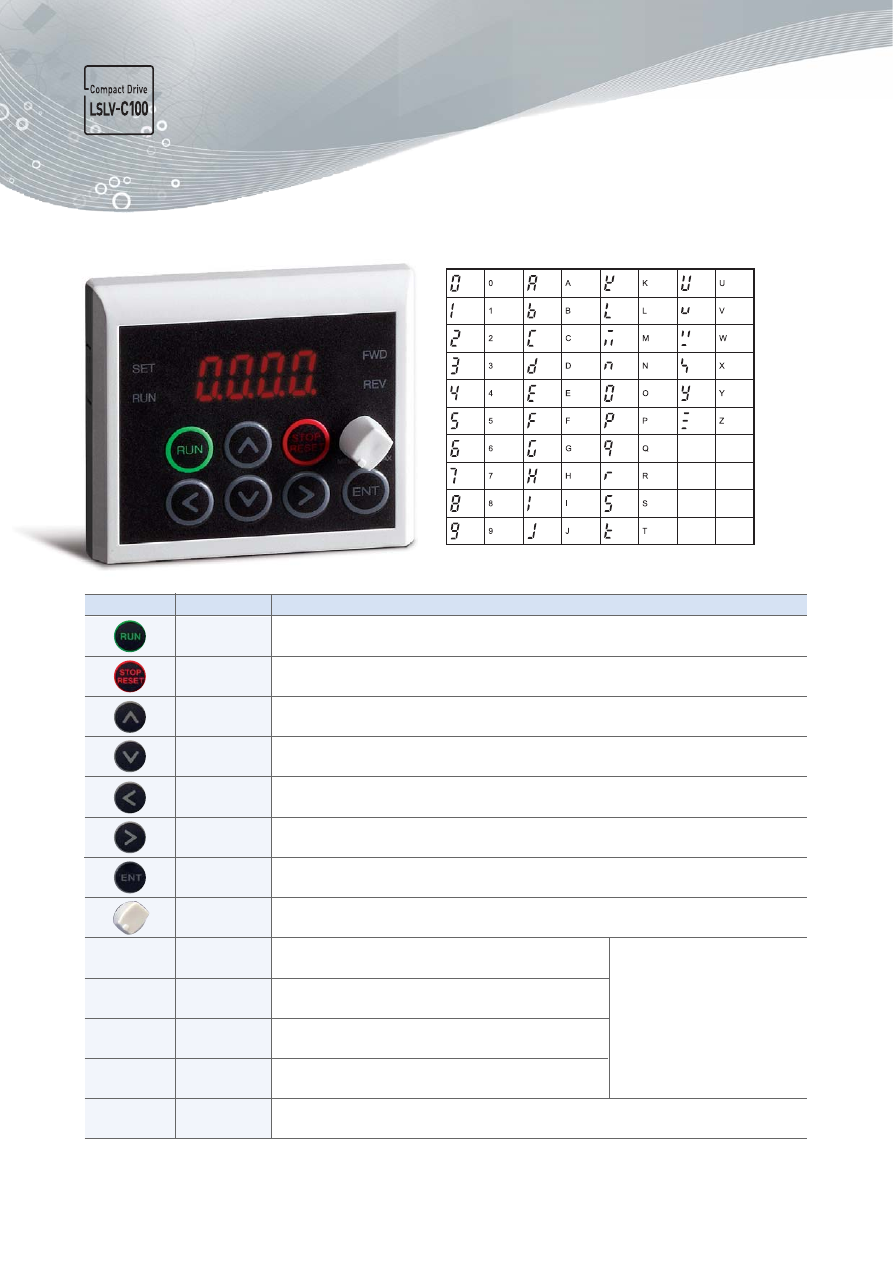

Keypad Usage & Function

RUN

STOP/RESET

Up

Down

Left

Right

ENT

Volume

Forward

Reverse

Running

Setting

Current Values

FWD

REV

RUN

SET

7-segment

STOP: Stop command during operation,

RESET: Reset command when fault occurs.

Used to switch parameter groups or move the cursor to the left when the

parameters are written.

Used to switch parameter groups or move the cursor to the right when the

parameters are written.

Used to read, write and keep the parameter values.

The keypad potentiometer V2 is used for frequency setting.

Lit during forward run

Lit during reverse run

Lit during operation

Lit during parameter setting

Operation data and parameter information are displayed.

Blinks when a fault occurs

Run command

Used to move parameter codes or increase parameter values

Used to move parameter codes or increase parameter values

Description

Display

Key

Alpha-numeric Table

14_15

Compact Drive LSLV-C100

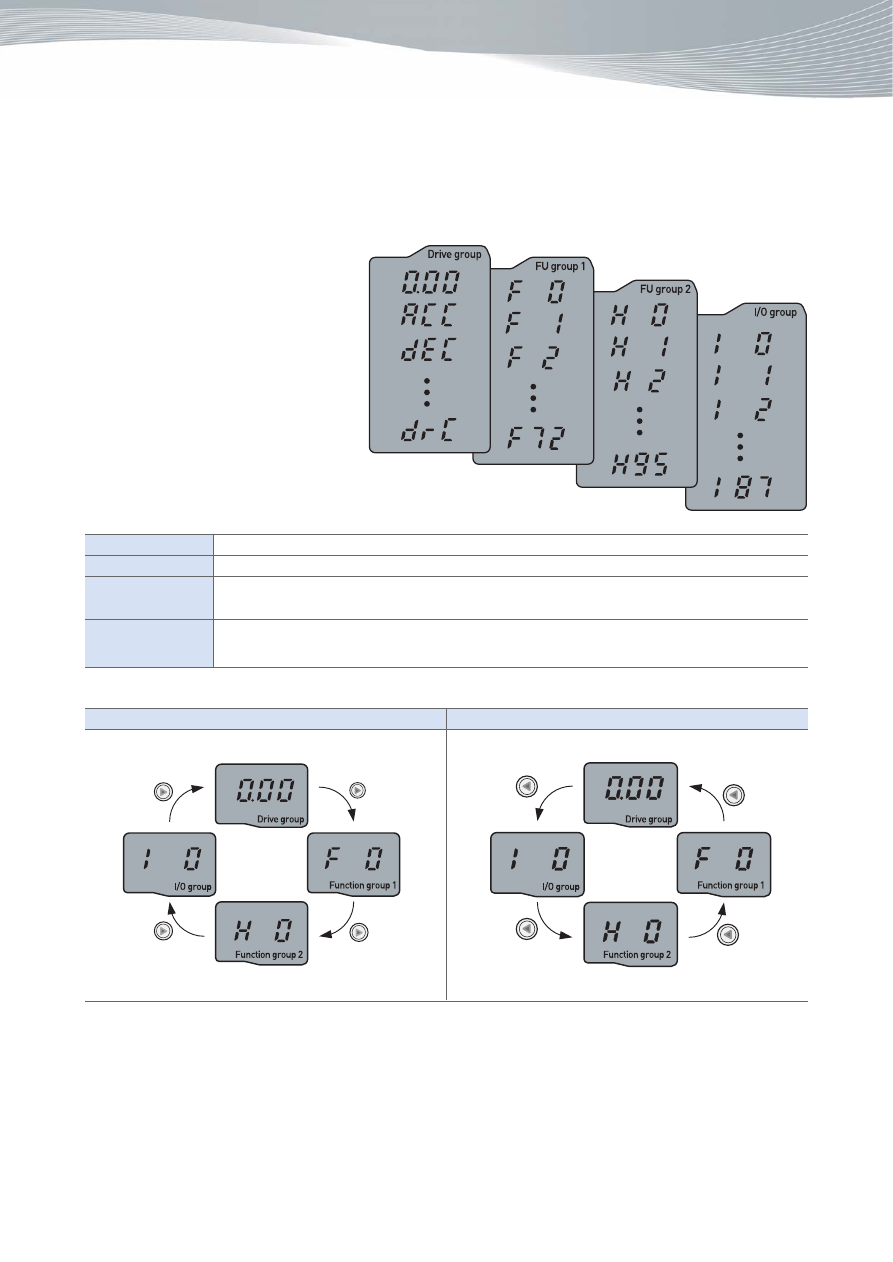

Moving to Other Parameter Groups & Codes

Moving to Other Parameter Groups

LSLV-C100 series product consists of the

following four parameter groups.

Moving to Other Parameter Groups Via the Right (

▶) Key.

Moving to Other Parameter Groups Via the Left (

◀) Key.

Note

1) Target frequency can be set at 0.0 (the 1st code of drive group). Even though the preset value is 0.0 while leaving factory, after setting of the target frequency,

the changed frequency value will be displayed.

Drive Group

Function Group 1

Function Group 2

I/O (input/output)

Terminal Function

Group

Set Basic parameters necessary for drive operation, including target frequency, Accel/Decel time and so on.

Set basic function parameters, such as adjustment of input frequency, voltage and so on.

Set advanced function parameters, for example, set application functions such as PID operation, second motor

operation and so on.

Set multi-function input/ output terminals and analog input/output parameters.

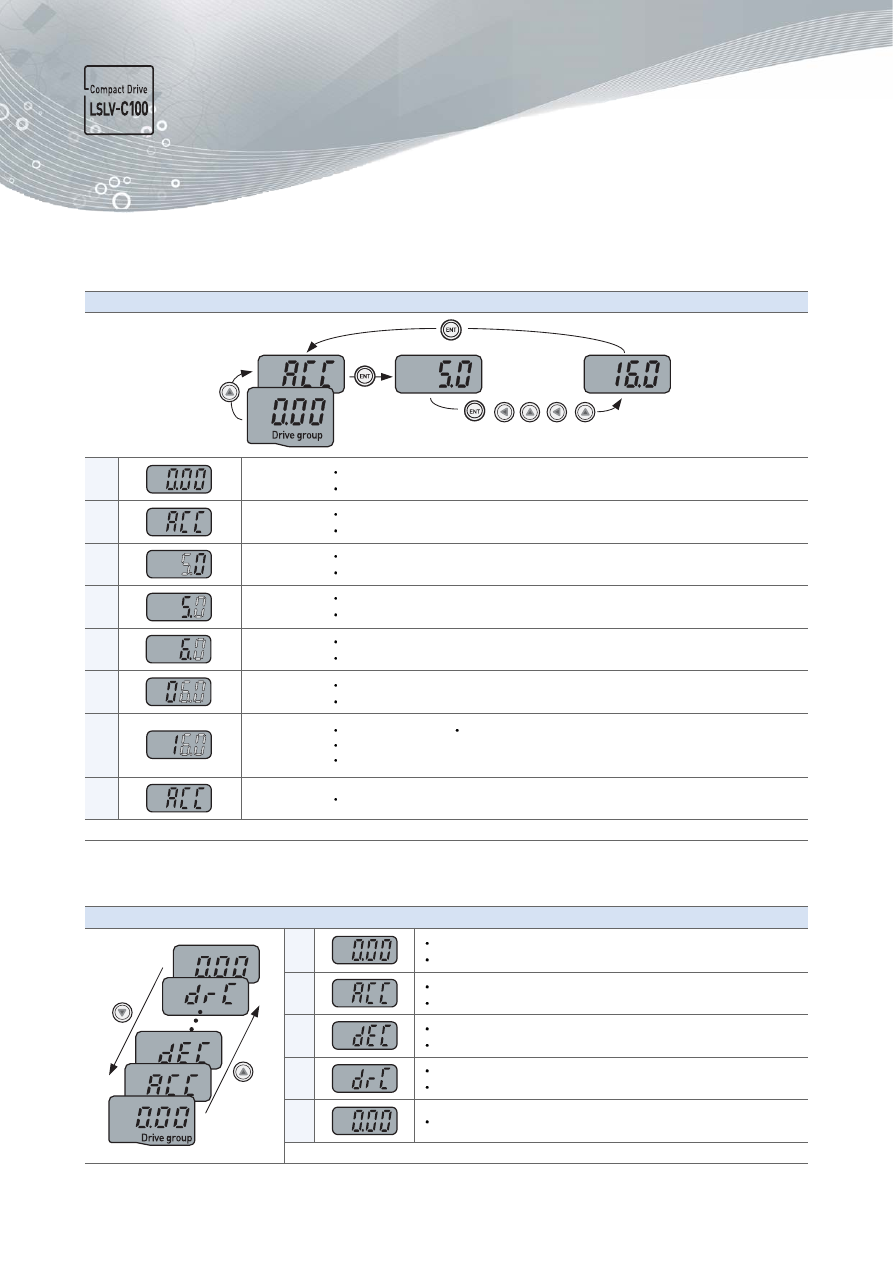

Moving to Other Parameter Groups & Codes

When Changing ACC Time From 5.0 sec to 16.0 sec

1

2

3

4

5

6

7

8

Code Change in Drive Group

The 1

st

code of the parameter group is displayed when the Power is applied

Press the Up (

▲) key.

The default code is 5.0 and the cursor is in the digit 0.

Press the Left (

◀) key once to move the cursor to the left.

The digit 5 is active, and then the parameter value can be changed.

Press the Up (

▲) key.

The value is increased to 6.0.

Press the Left (

◀) key to move the cursor to the left.

0.60 is displayed. The first 0 in 0.60 is active.

Press the Up (

▲) key once.

ACC is displayed. Accel time is changed to 16.0

Pressing the Left (

◀) or Right (▶) key while 16.0 is blinking will disable the setting.

16.0 is displayed.

Press the ENT key.

16.0 is blinking 1)

Press the ENT key once again to return to the parameter name.

The second code ACC of Drive group is displayed.

Press the ENT key.

Parameter Setting in Drive Group

Note

1) When the parameter value is changed, the blinking cursor means if any changed value is required,

then Press the ENT key to complete the input of parameter change. Press any key of (

◀)(▶)(▲)(▼) if any parameter change is cancelled.

1

2

3

4

5

The 1

st

code 0.00 of Drive group is displayed.

Press the Up (

▲) key once.

The 1

nd

code dEE of Drive group is displayed.

Keep pressing the Up (

▲) key until the last code appears.

The last code drC of Drive group is displayed.

Press the Up (

▲) key again.

Return to the first code of Drive group.

Use Down (

▼) key for the reverse order.

The 1

nd

code ACC of Drive group is displayed.

Press Up (

▲) key once.

16_17

Compact Drive LSLV-C100

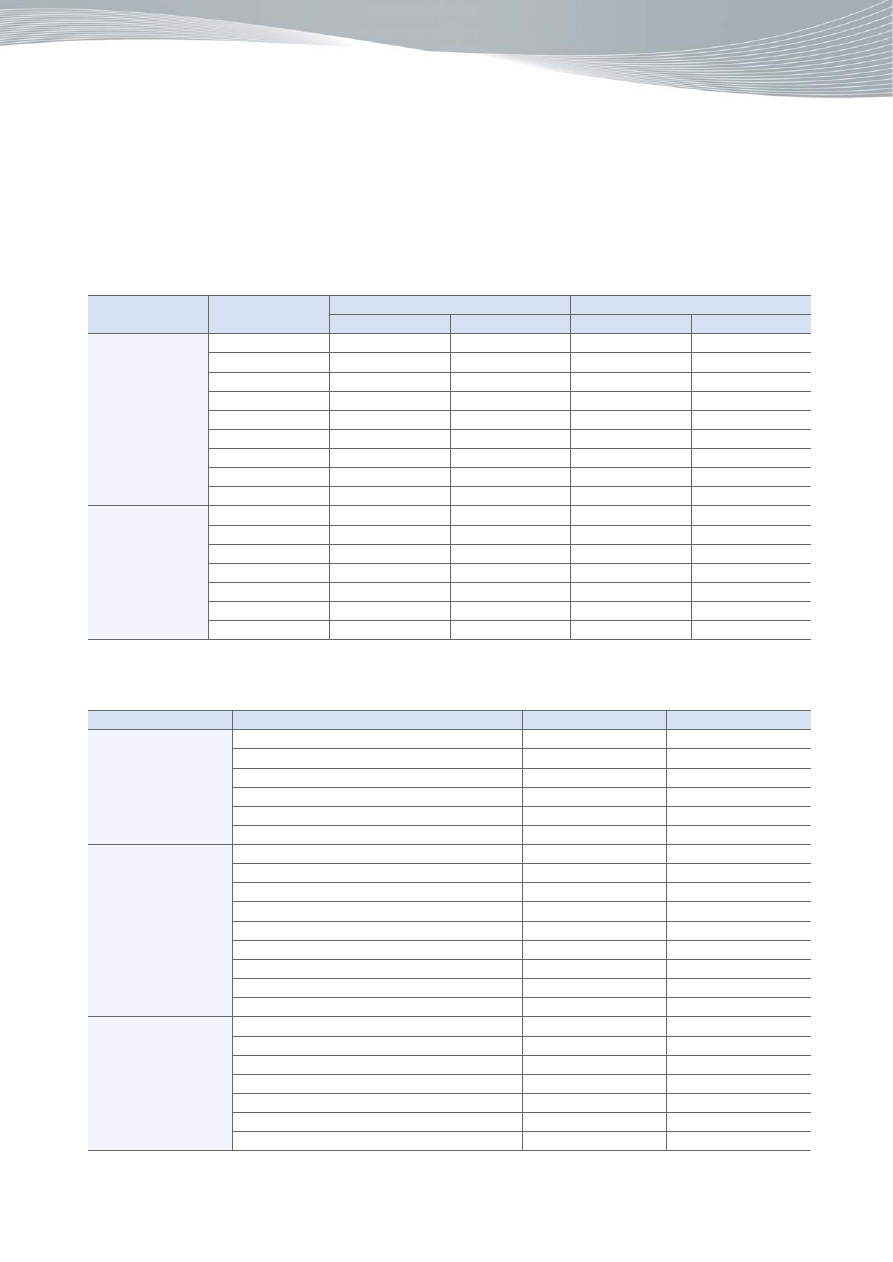

Braking Resistors and Peripheral Devices

Warning

1) MC(Magnetic Contactor) current is 1.5~2.0 times of Drive’s rated current

2) MCCB should be used to protect overload and to avoid damage of installation from the fault current(C100 has the overload capacity of 150% for 1 min)

Braking Resistors

Supply Voltage

Inv[kW]

100% Braking

Resistance[W]

P

*)

[W]

150% Braking

Resistance[W]

P

*)

[W]

200V

400V

0.1

0.2

0.4

0.75

1.5

2.2

3.7

5.5

7.5

0.4

0.75

1.5

2.2

3.7

5.5

7.5

1200

700

400

200

100

60

40

30

20

1800

900

450

300

200

120

90

1000

500

300

150

60

50

33

20

15

1200

600

300

200

130

85

60

20

25

50

100

200

300

500

700

1000

50

100

200

300

500

700

1000

20

35

100

150

300

400

600

800

1200

100

150

300

400

600

1000

1200

Peripheral Devices

Input Voltage

Drive Model

ELCB

MC

1 Phase 200V

3 Phase 200V

3 Phase 400V

LSLV0001C100-1

LSLV0002C100-1

LSLV0004C100-1

LSLV0008C100-1

LSLV0015C100-1

LSLV0022C100-1

LSLV0001C100-2

LSLV0002C100-2

LSLV0004C100-2

LSLV0008C100-2

LSLV0015C100-2

LSLV0022C100-2

LSLV0037C100-2

LSLV0055C100-2

LSLV0075C100-2

LSLV0004C100-4

LSLV0008C100-4

LSLV0015C100-4

LSLV0022C100-4

LSLV0037C100-4

LSLV0055C100-4

LSLV0075C100-4

EBS33c

EBS33c

EBS33c

EBS33c

EBS33c

EBS33c

EBS33c

EBS33c

EBS33c

EBS33c

EBS33c

EBS33c

EBS33c

EBS53c

EBS53c

EBS53c

EBS53c

EBS53c

EBS53c

EBS53c

EBS53c

EBS53c

MC-9a/9b

MC-9a/9b

MC-9a/9b

MC-9a/9b

MC-12a/12b

MC-18b

MC-9a/9b

MC-9a/9b

MC-9a/9b

MC-9a/9b

MC-12a/12b

MC-18b

MC-32a

MC-40a

MC-50a

MC-9a/9b

MC-9a/9b

MC-9a/9b

MC-12a/12b

MC-18b

MC-32a

MC-32a

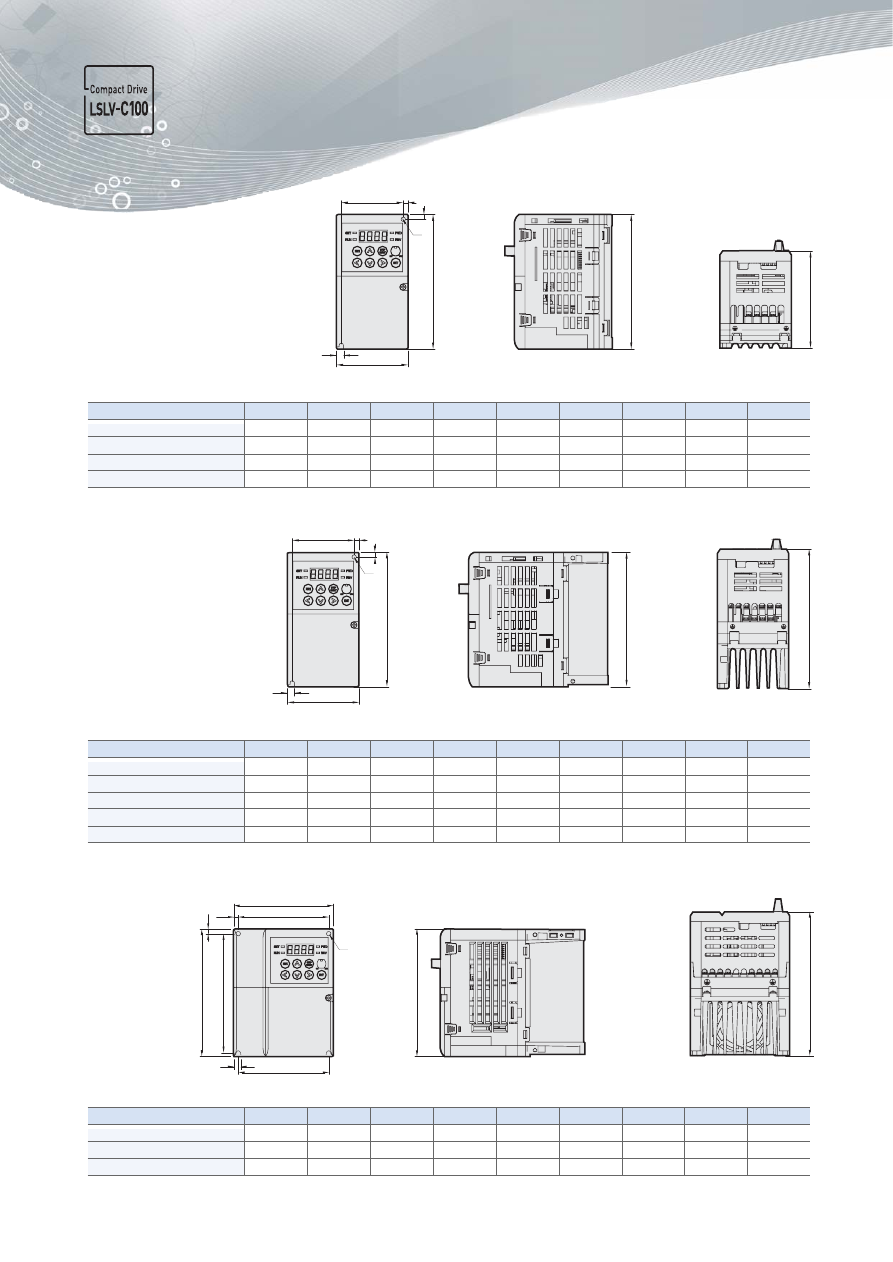

Dimensions

W

B

W

W1

A

A

Ø

H

H

H1

D

0001C100-1 / 0002C100-1 / 0001C100-2 / 0002C100-2

LSLV0001C100-1

LSLV0002C100-1

LSLV0001C100-2

LSLV0002C100-2

Drive Volume

W

W1

H

H1

D

A

B

kg

∅

68

68

68

68

63.5

63.5

63.5

63.5

128

128

128

128

124.5

124.5

124.5

124.5

93

93

93

93

4.2

4.2

4.2

4.2

4.5

4.5

4.5

4.5

4.2

4.2

4.2

4.2

0.55

0.55

0.55

0.55

(unit : mm, kg)

0004C100-1 / 0004C100-2 / 0008C100-2 / 0004C100-4 / 0008C100-4

LSLV0004C100-1

LSLV0004C100-2

LSLV0008C100-2

LSLV0004C100-4

LSLV0008C100-4

Drive Volume

W

W1

H

H1

D

A

B

kg

∅

68

68

68

68

68

63.5

63.5

63.5

63.5

63.5

128

128

128

128

128

124.5

124.5

124.5

124.5

124.5

128

128

128

128

128

4.2

4.2

4.2

4.2

4.2

4.5

4.5

4.5

4.5

4.5

4.2

4.2

4.2

4.2

4.2

0.8

0.8

0.8

0.8

0.8

(unit : mm, kg)

0008C100-1 / 0015C100-2 / 0015C100-4

LSLV0008C100-1

LSLV0015C100-2

LSLV0015C100-4

Drive Volume

W

W1

H

H1

D

A

B

kg

∅

100

100

100

91

91

91

128

128

128

120

120

120

130

130

130

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

1.22

1.22

1.22

(unit : mm, kg)

W

B

W1

A

A

Ø

H

H

D

W

B

W1

A

A

Ø

H

H

D

18_19

Compact Drive LSLV-C100

W

B

W

W1

A

A

Ø

H

H

H1

D

B

W

W1

A

A

Ø

H

H1

D

B

W

W1

Ø

H

H1

A

D

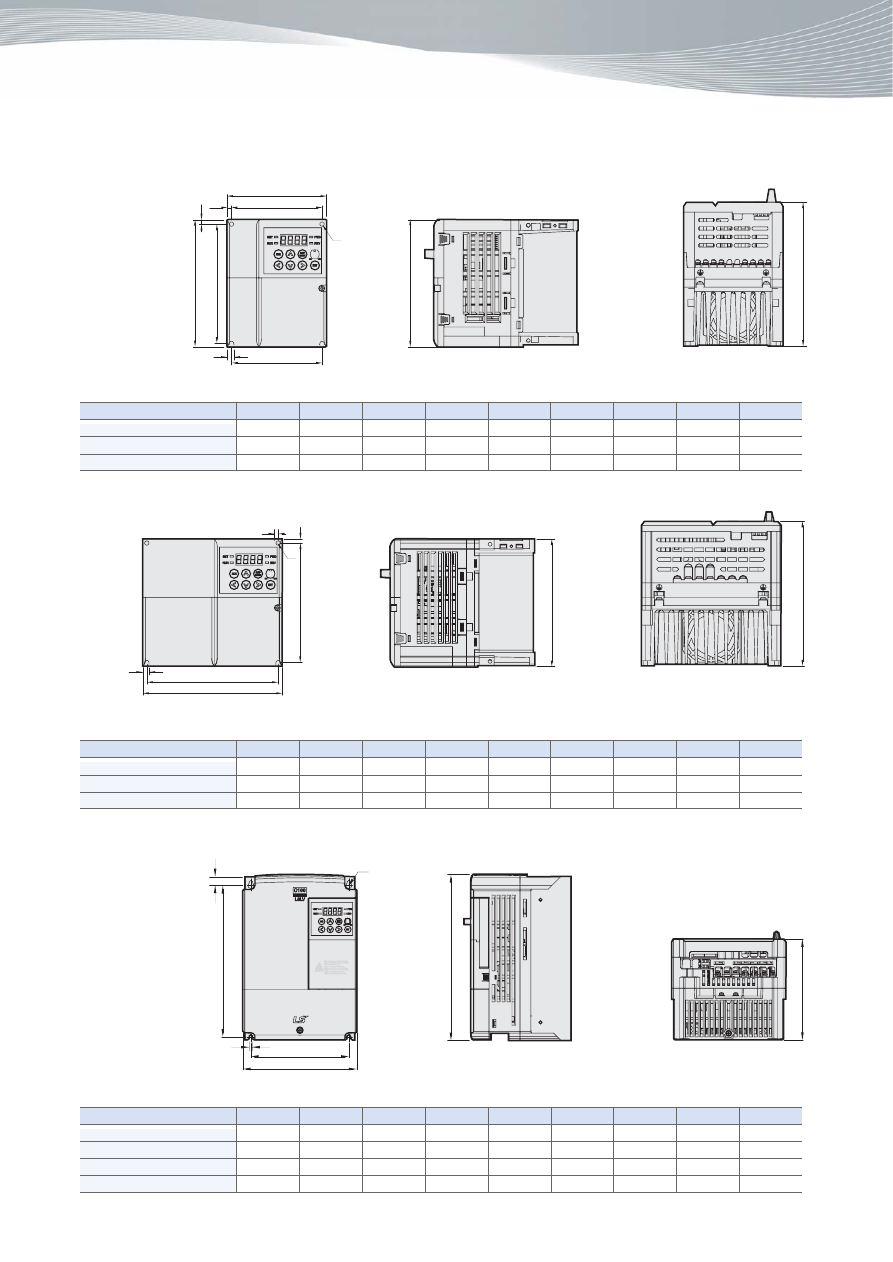

0055C100-4 / 0075C100-4

LSLV0055C100-2

LSLV0075C100-2

LSLV0055C100-4

LSLV0075C100-4

Drive Volume

W

W1

H

H1

D

A

B

kg

∅

160

160

160

160

137

137

137

137

232

232

232

232

216.5

216.5

216.5

216.5

141

141

141

141

5

5

5

5

10.5

10.5

10.5

10.5

5

5

5

5

3.3

3.3

3.3

3.4

(unit : mm, kg)

0015C100-1 / 0022C100-2 / 0022C100-4

LSLV0015C100-1

LSLV0022C100-2

LSLV0022C100-4

Drive Volume

W

W1

H

H1

D

A

B

kg

∅

100

100

100

91

91

91

128

128

128

120

120

120

145

145

145

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

1.42

1.42

1.42

(unit : mm, kg)

0022C100-1 / 0037C100-2 / 0037C100-4

LSLV0022C100-1

LSLV0037C100-2

LSLV0037C100-4

Drive Volume

W

W1

H

H1

D

A

B

kg

∅

140

140

140

132

132

132

128

128

128

120

120

120

145

145

145

4.5

4.5

4.5

4

4

4

4.5

4.5

4.5

1.97

1.97

1.97

(unit : mm, kg)

�

�

For your safety, please read user's manual thoroughly before operating.

�

�

Contact the nearest authorized service facility for examination, repair, or adjustment.

�

�

Please contact qualified service technician when you need maintenance.

Do not disassemble or repair by yourself

!

�

�

Any maintenance and inspection shall be performed by the personnel having expertise concerned.

Safety Instructions

LSIS(Shanghai) Co., Ltd. /CHINA

32nd Floor, International Corporate City, No.3000 NorthZhongshan Road,

Putuo District, Shanghai, China, 200063

Tel : 86-21-5237-9977(609) Fax : 86-21-5237-7189

LSIS(Wuxi) Co., Ltd./CHINA

102-A, National High & New Tech Industrial Development Area, Wuxi, Jiangsu, P.R. China

Tel : 86-510-8534-6666~8005 Fax : 86-510-8534-4078 E-Mail : sojin@lsis.com

LS Hukai Electric(Hubei) Co., Ltd./CHINA

No. 100, Tanjiahe Road, Dianjun District, Yichang City, Hubei Province, P.R. China

Tel : 86-717-667-7339 Fax : 86-717-667-7559 E-Mail : jaewoongh@lsis.com

LS-VINA Industrial Systems Co., Ltd./VIETNAM

Nguyen Khe, Dong Anh, Hanoi, Vietnam

Tel : 84-4-6275-8055 Fax : 84-4-3882-0220

LSIS(ME) FZE/U.A.E.

LOB 19-205, JAFZA View Tower, Jebel Ali Free Zone, Dubai, United Arab Emirates

Tel : 971-4-886-5360 Fax : 971-4-886-5361 E-Mail : shunlee

@

lsis.com

LSIS Europe B.V./NETHERLANDS

1st. Floor, Tupolevlaan 48, 1119NZ,Schiphol-Rijk, The Netherlands

Tel : 31-20-654-1420 Fax : 31-20-654-1429 E-Mail : eropartner@lsis.com

LSIS Japan Co., Ltd./JAPAN

Tokyo Club Building 13F, 2-6, Kasumigaseki 3-chome, Chiyoda-ku, Tokyo, 100-0013

Tel : 81-3-6268-8241 Fax : 81-3-6268-8240 E-Mail : jschuna@lsis.com

LSIS USA Inc./U.S.A.

2000 Millbrook Drive, Lincolnshire, Chicago, IL 60069, United States of America

Tel : 1-847-941-8240 Fax : 1-847-941-8259

LSIS Shanghai Office/CHINA

R32nd Floor, International Corporate City, No.3000 NorthZhongshan Road, Putuo District,

Shanghai, China, 200063

Tel : 86-21-5237-9977(702) Fax : 86-21-5237-7189

LSIS Beijing Office/CHINA

Room 2306, Building B Landgent Center, No.24 Middle Road, East 3rd Ring Road,

Chaoyang District, Beijing, P.R. China

Tel : 86-10-5761-3127 Fax : 86-10-5761-3128 E-Mail : htroh

@

lsis.com

LSIS Guangzhou Office/CHINA

RRoom 1818-1820, Xinyuan Building,NO.898 Tianhe North Road, Tianhe District,

Guangzhou, P.R China

Tel : 86-20-8326-6784 Fax : 86-20-8326-6287 E-Mail : htroh@lsis.com

LSIS Qingdao Office/CHINA

Room 2001, Galaxy Building, 29 ShanDong Road, ShiNan District, QingDao, ShanDong, P.R. China

Tel : 86-532-8501-6058 Fax : 86-532-8501-6057 E-Mail : htroh

@

lsis.com

LSIS Chengdu Office/CHINA

Room1710, 17/F Huamin Empire Plaza, NO.1 Fuxin Road, Chengdu, P.R. China

Tel : 86-28-8670-3201 Fax : 86-28-8670-3203 E-Mail : yangcf

@

lsis.com

LSIS ShenYang Office/CHINA

Room 803, Hongyuan Building, 52 South Nanjing Road,Heping District, Shenyang, P.R. China

Tel : 86-24-2321-9050 Fax : 86-24

-8386-7210 E-Mail : yangcf

@

lsis.com

LSIS Jinan Office/CHINA

Room 317, Chuangzhan Center, No. 201, Shanda Road, Lixia District, Jinan, Shandong, P. R. China

Tel : 86-531-8699-7826 Fax : 86-531-8697-7628 E-Mail : yangcf@lsis.com

LSIS Tokyo Office/JAPAN

Tokyo Club Building 13F, 2-6, Kasumigaseki 3-chome, Chiyoda-ku, Tokyo, 100-0013

Tel : 81-3-6268-8241 Fax : 81-3-6268-8240

LS-VINA Industrial Systems Hochiminh Office/VIETNAM

Gema Dept Tower 18F, 6 Le Thanh Ton, District 1, HCM, Vietnam

Tel : 84-8-3823-7890 E-Mail : sjbaik

@

lsis.com

LSIS Detroit Office/U.S.A.

5700 Crooks Rd, Suite 211, Troy, MI 48098, United States of America

Tel : 1-248-792-2637~8 Fax : 1-248-792-2642 E-Mail : sylee

@

lsis.com

LSIS Gurgaon Office/INDIA

109 First Floor, Park Central, Sector-30, Gurgaon- 122 002, Haryana, India

Tel : 91-1244-930-077 Fax : 91-1244-930-066 E-Mail : hwyim

@

lsis.com

LSIS Moscow Office/RUSSIA

123610, Krasnopresnenskaya, nab., 12, building 1, office ¢‡1005, Moscow, Russia

Tel : 7-495-258-1466/1467 Fax : 7-495-258-1466/1467 E-Mail : jdpark1@lsis.com

LSIS U.K Office/United Kingdom

G17 Bedford I-Lab, Stannard Way, Priory Business Park, Bedford, MK44 3RZ, U.K.

Tel : 44-012-3483-4774 Fax : 44-012-3483-4775

2014. 10

Compact Drive LSLV-C100 (E)_2014.07 / (02) 2014.10 Printed in Korea_

HumanPower

ⓒ

ⓒ

2014.07 LSIS Co., Ltd. All Rights Reserved.

Overseas Branches

Overseas Subsidiaries

Specifications in this catalog are subject to change without notice due to continuous product

development and improvement.

■ Europe & Middle East

Tel : 82-2-2034-4901

bonseongk

@

lsis.com

■ Africa

Tel : 82-2-2034-4967 sjleeq

@

lsis.com

■ Asia Pacific

Tel : 82-2-2034-4620 mswoo

@

lsis.com

HEAD OFFICE

LS Tower, 127, LS-ro, Dongan-gu, Anyang-si, Gyeonggi-Do, 431-848, Korea